Getting to the valves

You should have the cam cover off at this stage and ready to attack the valve train. First thing you need to do is to check your valve clearances to see if any shim replacement is in order.

With the bike on the stand and in 5th gear (spark plugs removed?) rotate the rear tire until the lobes on the cams are pointing AWAY from the valve shims. You will be able to measure 2 valves at a time each time you get one of the lobes aligned in this manner.

Take a measurement between the valve shim and the bottom of the lobe. WRITE THESE MEASUREMENTS DOWN!

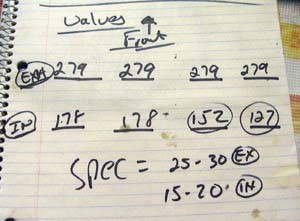

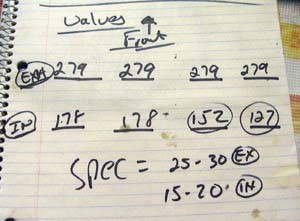

This is my worksheet I wrote up and the measurements of each gap. The two that are circled are out of spec and need replacing. To figure what size shim I need I wrote Pat's Shim Calculator Program

Once you have the specs written down, it's time to pull the overhead cams out.

WARNING! If you are not an experienced mechanic and have never pulled cylinders out of a motorcycle before, please re-consider doing anything else, refer the job to someone that knows what they are doing. If you mess these next parts up you may destroy your motor. Consider yourself warned!

A good start is to align the gears up so that the cylinders are at top dead center. Do this by turning the rear wheel until the gears are aligned as shown in this picture. The service manual also has a good example of this.

Notice the cam lobe positions and that there is a large mark on the top of the large cam alignment gear where the screwdriver is pointing. This is the proper alignment you will look for when you put it all back together. On the backside of each cam gear there are also little marks that will all line up with each other. Take a good look from both sides to see what I mean. This will be the reference you want later as well. Notice the wiring is in the way, see, I should have tied it out of the way earlier. It came back to bite me in the ass. I didn't mess anything up, just wasted a lot of time working around it.

Start by shoving some rags all around in any hole that crap might fall down into the motor. You will be removing a lot of nuts and washers and do not want anything to fall into the motor. If it does, go inside and cry, you're screwed and have a big job ahead of you.

You must now insert your backlash retainers into each cam gear to prevent the gears from moving when removed. Got rags stuffed into the holes?

Notice the cam lobe positions and that there is a large mark on the top of the large cam alignment gear where the screwdriver is pointing. This is the proper alignment you will look for when you put it all back together. On the backside of each cam gear there are also little marks that will all line up with each other. Take a good look from both sides to see what I mean. This will be the reference you want later as well. Notice the wiring is in the way, see, I should have tied it out of the way earlier. It came back to bite me in the ass. I didn't mess anything up, just wasted a lot of time working around it.

Start by shoving some rags all around in any hole that crap might fall down into the motor. You will be removing a lot of nuts and washers and do not want anything to fall into the motor. If it does, go inside and cry, you're screwed and have a big job ahead of you.

You must now insert your backlash retainers into each cam gear to prevent the gears from moving when removed. Got rags stuffed into the holes?

If the cam gears come un-sprung, you must get them re-sprung and retained before attempting re-istallation. My retainers are simple screws that have been filed down to fit. I tapped them in with my little bitty hammer and a 1x1 piece of pine. They were made and sent to me by BA.com Member BUDWEISER, Thanks BUD! I really appreciate them.

If the cam gears come un-sprung, you must get them re-sprung and retained before attempting re-istallation. My retainers are simple screws that have been filed down to fit. I tapped them in with my little bitty hammer and a 1x1 piece of pine. They were made and sent to me by BA.com Member BUDWEISER, Thanks BUD! I really appreciate them.

Now we are gonna pull the caps off of the cams.

First remove the camshaft oilpipe's two bolts and wiggle it out. There is an o-ring in the one side that you will replace when you put it back together.Now to the caps; This is where the nice hard T-30 torx bit comes into play. You want to loosen all the caps working in a crisscross pattern. Just break each one loose then once they are all broken loose, remove them in the same criss cross order. Be sure to note that the caps have a front and a back and that every parts ends up going back in the EXACT same place. GENTLY remove both cams and place them on the table with all the other camshaft parts.I laid mine all out and labeled them like the picture below.

Next Step

Next Step

Back to the main page